Welcome to ARNIX ROBOTIX!

My name is Arnaud and I am an embedded software engineer.

I have ten years of experience in embedded systems with a strong interest in robotics and automatic control.

My skills include design, implementation and integration of software and I am also comfortable with devices such as debuggers, oscilloscopes and logic analysers.

During my previous work experiences, I worked in multiple domains such as Aerospace, Automotive, Agricultural machinery or Robotics.

I gained a broad knowledge of the challenges faced while developping embedded products and built strong capabilities to overcome them.

I love a good challenge and enjoy research as part of my job.

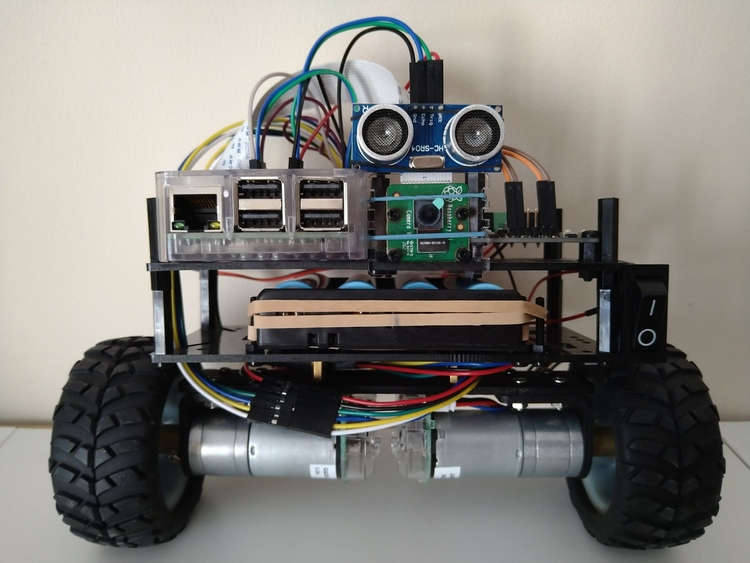

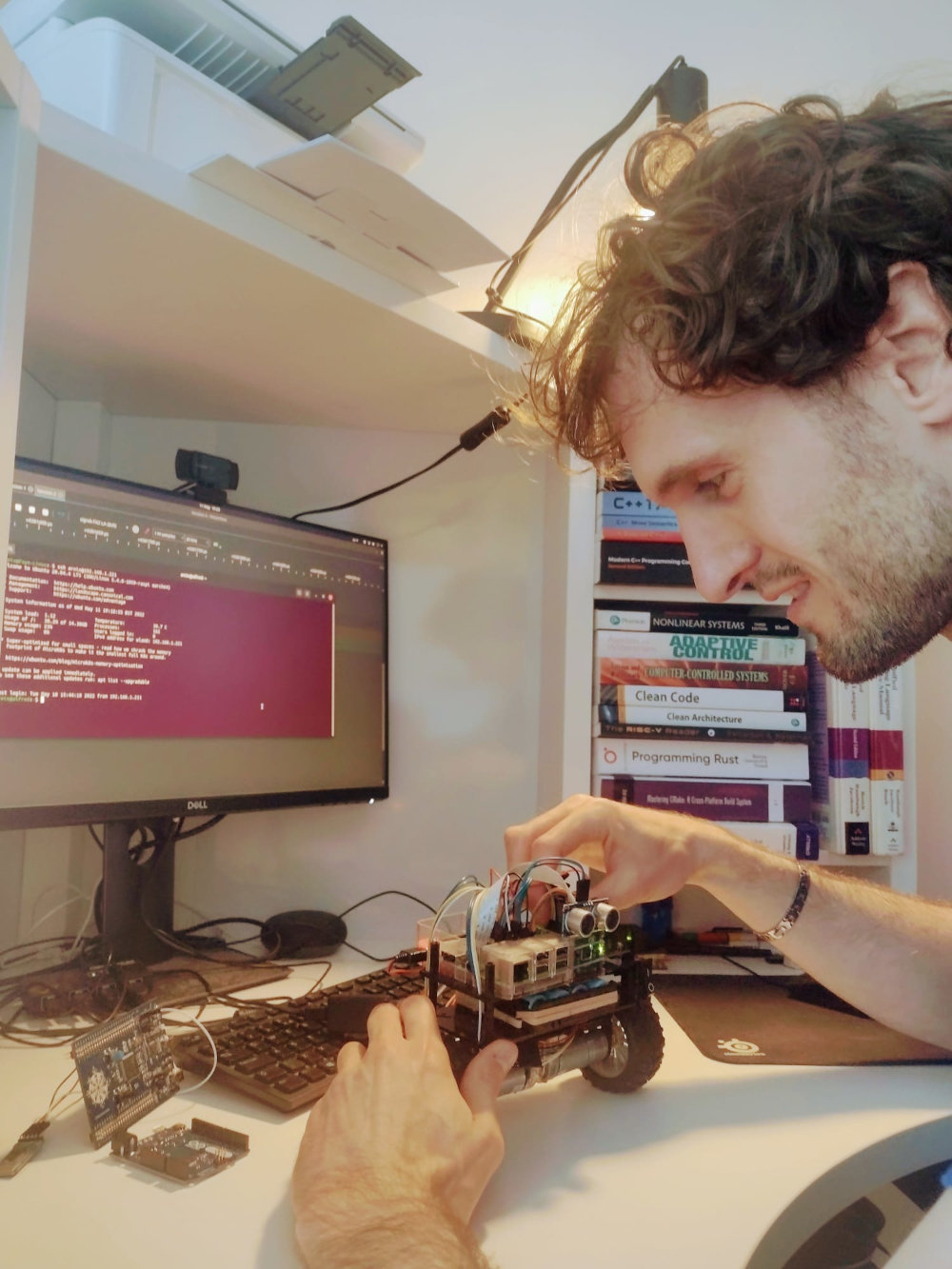

Alfred is a self-balanced, two-wheel robot based on a Raspberry Pi.

- Raspberry Pi,

- two motors with quadrature encoders (controlled with PWM signals),

- an IMU (with an I2C interface),

- an ultrasonic proximity sensor,

- a Raspberry Pi camera.

I am using this project to apply new skills I am learning through books and online courses.

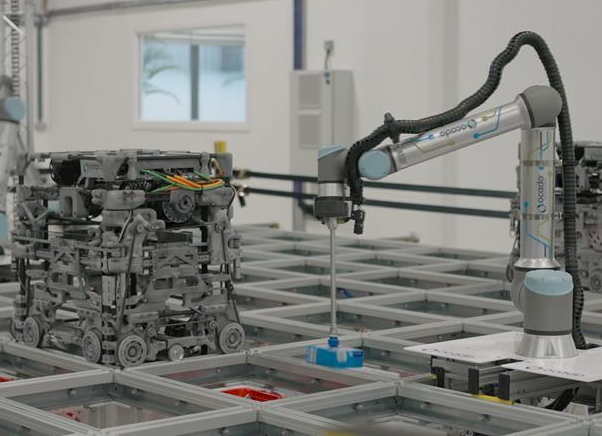

This project aimed at porting the motion control strategies of a line of robots to an older one, built with different hardware architecture.

To achieve this goal, the team had to gradually introduce changes to the code without altering the performances of the robots already used in production sites.

The new motion control strategies were successfully tested on a small fleet of robots.

- Xpress restart, that allows the operator to declutch only using the brake pedals

- Multispeed steering, that allows the operator to turn with less steering wheel turns at low speed

This project was developed for Mercedes E Class cars.

The charger was located in the centre console.

I integrated and configured an already developed RAM checking module.

I successfully demonstrated the module's behaviour to the client and the charger was put into production.

The main goal of this project was to upgrade the existing device.

It was possible to build the project using both toolchains and I could demonstrate successfully a proof of concept of the OTA update feature.

You did not fill out the required fields.

Close